Ferritic stainless steel is a type of stainless steel that offers a wide range of uses and applications due to its unique composition and properties. This type of stainless steel is known for its high chromium content, which provides excellent resistance to corrosion and oxidation. Additionally, ferritic stainless steels are magnetic and have good toughness, making them suitable for various industries and applications.

One of the most common uses of ferritic stainless steel is in the automotive industry. Ferritic stainless steel grades such as Nitronic 50HS are used for manufacturing exhaust systems, mufflers and other components that require high resistance to corrosion and heat. The ferritic composition of this material allows it to withstand the extreme temperatures and harsh environmental conditions found in vehicle exhaust systems.

Another important application of ferritic stainless steel is in the construction industry. Ferritic stainless steels offer excellent strength and durability, making them suitable for structural applications such as bridges, buildings and infrastructure. These steels can withstand heavy loads and have good resistance to corrosion, making them a cost-effective choice for construction projects.

| Ferritic Stainless Steel Grade | Composition | Properties |

|---|---|---|

| SUS430 | 17-20% chromium, less than 0.12% carbon, less than 1% manganese | Good corrosion resistance, magnetic, moderate strength |

| Ferritic Steel | 10.5-30% chromium | High resistance to corrosion and oxidation, magnetic |

Ferritic stainless steel offers a wide range of applications and uses due to its unique composition and properties. Whether it’s in the automotive industry, construction or other industries, ferritic stainless steels prove to be versatile and reliable materials. With their excellent resistance to corrosion, heat and toughness, ferritic stainless steels continue to be a popular choice for various applications.

Understanding Ferritic Stainless Steel

Ferritic stainless steel is a type of stainless steel that belongs to the ferritic group of alloys. It is known for its high corrosion resistance and excellent heat resistance. Ferritic stainless steel can be identified by its magnetic properties, as it contains high levels of ferrite, a crystalline iron compound.

Ferritic stainless steel grades, such as SUS430, are often chosen for their affordability and ease of fabrication. Additionally, ferritic stainless steel is also utilized in appliances, including ovens, refrigerators and dishwashers, due to its ability to withstand high temperatures and resist corrosion caused by food and water.

Ferritic stainless steel properties:

- Excellent corrosion resistance

- High heat resistance

- Good formability and weldability

- High strength and durability

- Relatively low cost compared to other stainless steel types

One of the key uses of ferritic stainless steel is in the construction industry. It is commonly used in the production of architectural structures and building cladding due to its aesthetic appeal and resistance to atmospheric corrosion. This makes ferritic stainless steel a popular choice for exterior applications where exposure to harsh weather conditions is expected.

| Grade | Composition | Applications |

|---|---|---|

| SUS430 | 17-20% chromium, < 0.12% carbon | Automotive components, appliances, architectural structures |

| SUS439 | 17-20% chromium, 0.03% carbon, < 0.5% molybdenum | Exhaust systems, automotive trim, furnace components |

| SUS444 | 17.5-19.5% chromium, 2-2.5% molybdenum, < 0.025% carbon | Heat exchangers, condenser tubing, food processing equipment |

Overall, ferritic stainless steel offers a range of benefits and is widely used in various industries due to its corrosion resistance, heat resistance and cost-effectiveness. It is important to carefully select the appropriate ferritic stainless steel grade based on the specific application to ensure optimal performance and longevity.

Definition and Characteristics

Ferritic stainless steel is a type of stainless steel that belongs to the ferritic family of alloys. It is known for its high chromium content, which gives it excellent resistance to corrosion and oxidation. Ferritic stainless steel is different from other types of stainless steel, such as austenitic or martensitic, due to its low carbon content and high chromium content. This combination of elements results in a material that is both strong and corrosion-resistant.

The composition of ferritic stainless steel typically includes around 10-30% chromium and small amounts of carbon, molybdenum, and sometimes nickel. This alloying composition provides ferritic stainless steel with its unique properties. One of the main characteristics of ferritic stainless steel is its magnetic nature, making it attractive for applications that require magnetic property, such as in electrical motors and transformers. Additionally, ferritic stainless steel has good heat resistance, making it suitable for high-temperature applications.

| Ferritic Stainless Steel | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| High chromium content | High nickel content | High carbon content |

| Low carbon content | Low carbon content | Low carbon content |

| Magnetic | Non-magnetic | Magnetic |

| Good heat resistance | High corrosion resistance | High hardness |

Ferritic stainless steel is commonly used in automotive applications, such as exhaust systems and catalytic converters, where its resistance to high temperatures and corrosion is essential. The low carbon content of ferritic stainless steel also makes it suitable for welding and fabrication processes. Additionally, this type of stainless steel is used in the manufacture of kitchen appliances, such as sinks and refrigerators, as well as in the construction industry for architectural purposes. Overall, ferritic stainless steel provides a cost-effective solution for applications that require strength, corrosion resistance, and magnetic properties.

Distinction from other stainless steel types

Unlike austenitic stainless steels, which are known for their excellent corrosion resistance, ferritic stainless steels have lower corrosion resistance, but they offer several other advantages.

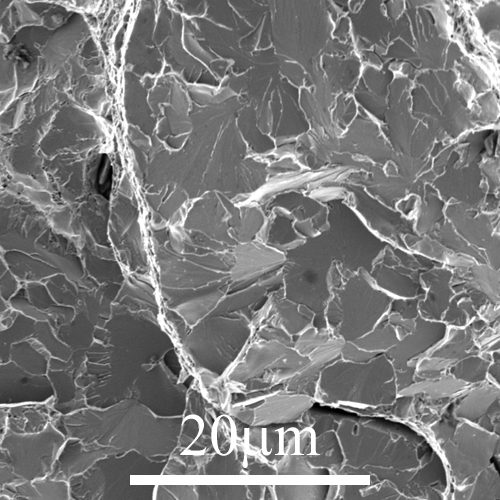

One important distinction is their ferritic structure, which consists of a body-centered cubic crystal lattice. This structure gives ferritic stainless steels their magnetic properties, unlike austenitic steels, which are non-magnetic. The ferritic structure also provides good ductility and toughness, making them suitable for various applications.

Ferritic stainless steels are typically alloyed with chromium to enhance their corrosion resistance and improve their mechanical properties. The chromium content in ferritic stainless steels is generally lower than in austenitic steels, which reduces their cost. This makes ferritic stainless steels a more cost-effective option for applications where corrosion resistance is not the primary concern.

| Property | Ferritic Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Corrosion Resistance | Lower | Higher |

| Magnetic Properties | Yes | No |

| Ductility | Good | High |

| Toughness | Good | High |

| Price | Lower | Higher |

Applications of Ferritic Stainless Steel

Ferritic stainless steel is a type of stainless steel that is primarily composed of iron and chromium, with small amounts of other elements such as nickel, manganese, and carbon. It has a ferritic crystal structure, which gives it its unique properties and makes it suitable for a wide range of applications.

One of the main applications of ferritic stainless steel is in the automotive industry. It is commonly used for manufacturing exhaust systems, as it has excellent resistance to high temperatures and corrosion. Ferritic stainless steel grades such as Nitronic 50HS have been specifically designed for this purpose, as they can withstand the harsh conditions of exhaust gases without corroding or deforming.

Ferritic stainless steel is often used for manufacturing architectural components, such as facades, handrails, and decorative elements. Its corrosion resistance makes it well-suited for outdoor applications, where it is exposed to moisture and other environmental factors. Additionally, ferritic stainless steel is relatively easy to fabricate and weld, making it a cost-effective and versatile choice for construction projects.

| Ferritic Stainless Steel Grade | Composition | Properties | Price |

|---|---|---|---|

| SUS430 | 17% to 19% chromium, 0.12% carbon, 1% or less manganese, 0.04% or less phosphorus, 0.03% or less sulfur, 1% or less silicon | Good corrosion resistance, high heat resistance, poor weldability, low toughness | Relatively low |

The versatility of ferritic stainless steel makes it a valuable material for various industries and applications. From automotive exhaust systems to architectural components, its unique combination of properties such as corrosion resistance, heat resistance, and ease of fabrication make it a preferred choice for many manufacturers and engineers.

Automotive Industry Uses of Ferritic Stainless Steel

The automotive industry extensively uses ferritic stainless steels due to their remarkable qualities and suitability for various applications. One notable grade in this category is Nitronic 50HS, a high-strength ferritic stainless steel. Its exceptional corrosion resistance and ability to withstand high temperatures make it ideal for exhaust systems and other components exposed to extreme conditions.

Ferritic stainless steels, in general, find multiple applications in the automotive sector. One common use is in the manufacturing of catalytic converters. These components, which help reduce harmful emissions, require materials that can withstand the high temperatures and corrosive environments within the exhaust system. Ferritic stainless steels, with their excellent corrosion resistance and resistance to thermal fatigue, provide the necessary durability and performance for catalytic converters.

SUS430 is a popular ferritic stainless steel material commonly used in automotive trim applications. Its aesthetic appeal, corrosion resistance, and affordable price make it an attractive choice for exterior components like door handles, bumper trims, and grilles. Additionally, its magnetic properties enable the use of reliable and efficient magnetic door catches and latches, enhancing the functionality and convenience of modern automobiles.

The composition of ferritic stainless steel plays a significant role in its automotive applications. The low carbon content in these steels makes them susceptible to high-temperature brittleness, limiting their use in certain engine components. However, they are extensively used in other areas where their corrosion resistance, mechanical strength, and cost-effectiveness outweigh any potential drawbacks.

| Applications | Examples |

|---|---|

| Exhaust Systems | Manifolds, mufflers, tailpipes |

| Trim Components | Door handles, bumper trims, grilles |

| Catalytic Converters | Substrates, heat shields |

| Structural Components | Brackets, supports |

In summary, ferritic stainless steels are widely used in the automotive industry for various applications. From high-strength exhaust systems to attractive trim components and durable catalytic converters, these versatile materials offer excellent corrosion resistance, thermal stability, and cost-effectiveness in automotive manufacturing.

Appliance Manufacturing Applications

Ferritic stainless steel grades have found numerous applications in the appliance manufacturing industry due to their unique properties and cost-effectiveness. One of the most commonly used ferritic stainless steel grades in this industry is SUS430, which is known for its excellent corrosion resistance, high strength, and good formability. It is widely used in the manufacturing of kitchen appliances, such as refrigerators, ovens, dishwashers, and microwaves.

Another popular ferritic stainless steel grade used in appliance manufacturing is Nitronic 50HS. This grade offers exceptional strength and high-temperature resistance, making it suitable for applications that require heavy-duty performance, such as industrial ovens and heating elements. Its low thermal expansion coefficient also ensures dimensional stability, making it an ideal choice for components that undergo frequent temperature changes.

| Ferritic Stainless Steel Grade | Composition | Uses |

|---|---|---|

| SUS430 | Iron (Fe), Chromium (Cr) | Kitchen appliances, automotive trim, architectural applications |

| Nitronic 50HS | Iron (Fe), Chromium (Cr), Nickel (Ni), Manganese (Mn) | Industrial ovens, heating elements, high-temperature applications |

Ferritic stainless steel grades have revolutionized the appliance manufacturing industry with their versatility and cost-effectiveness. These grades offer excellent corrosion resistance, strength, formability, and aesthetic appeal, making them the preferred choice for various appliances. Whether it’s a refrigerator, oven, dishwasher or microwave, ferritic stainless steel is a reliable material that ensures durability and high-performance.

Construction and Architecture

One of the key advantages of ferritic stainless steel is its excellent resistance to corrosion, making it an ideal choice for applications where exposure to moisture, chemicals, or other corrosive elements is likely. This corrosion resistance is particularly important in construction and architecture, where structures are often exposed to the elements and need to withstand long-term durability.

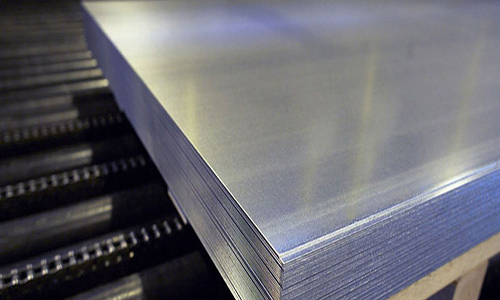

Another important property of ferritic stainless steel is its high strength, which makes it suitable for structural applications. This strength allows ferritic stainless steel to be used in the construction of buildings, bridges, and other infrastructure projects, providing a strong and reliable material that can support heavy loads. Additionally, ferritic stainless steel is highly formable, allowing it to be used in a variety of architectural designs and structures with complex shapes.

Ferritic Stainless Steel Applications in Construction and Architecture:

- Building facades: Ferritic stainless steel can be used to create stunning and modern building facades. Its corrosion resistance ensures that these facades remain in pristine condition for a long time, even in harsh environments.

- Bridges: Ferritic stainless steel grades such as Nitronic 50HS are commonly used in the construction of bridges due to their high strength and corrosion resistance. These steels can withstand the heavy loads and corrosive conditions associated with bridge construction.

- Roofing: Ferritic stainless steel is an excellent material for roofing applications, as it offers superior resistance to rust and corrosion. Its strength ensures that the roof can withstand extreme weather conditions and remain structurally sound.

In conclusion, ferritic stainless steel has numerous applications in the construction and architecture industries due to its corrosion resistance, strength, and formability. Its properties make it a reliable and durable material for building structures, facades, bridges, and roofing systems. The use of ferritic stainless steel in construction and architecture ensures that these structures can withstand the test of time and maintain their aesthetic appeal.

Exploring Ferritic Stainless Steel Grades

Ferritic stainless steel, such as SUS430 material, is a versatile and popular choice in various industries due to its unique properties and wide range of applications.

One of the main advantages of ferritic stainless steel is its resistance to corrosion, making it ideal for use in environments with high levels of moisture or exposure to corrosive substances. Its composition, which includes chromium and sometimes other alloying elements such as molybdenum or titanium, provides this corrosion resistance. This makes ferritic stainless steel a preferred choice for applications in the automotive industry, where durability and resistance to environmental factors are crucial.

- Ferritic stainless steel grades have excellent formability and can be easily welded, making them suitable for various fabrication processes. They are commonly used in the production of kitchen appliances, such as refrigerators, ovens, and dishwashers. The excellent formability of ferritic stainless steel allows for the creation of complex shapes and designs, ensuring the functionality and aesthetic appeal of these appliances.

- Ferritic stainless steel also offers high heat resistance, making it a reliable choice for applications in heat exchangers, furnaces, and other high-temperature environments. Its ability to withstand extreme temperatures without warping or losing its structural integrity makes it a preferred material for these applications.

- In terms of cost, ferritic stainless steel is generally more affordable compared to other stainless steel grades. This makes it an attractive option for industries that require cost-effective materials without compromising on quality or performance. Its availability and competitive pricing also contribute to its popularity in the market.

Ferritic stainless steel grades, such as SUS430 material, offer a wide range of applications and benefits. Their corrosion resistance, formability, heat resistance, and cost-effectiveness make them suitable for various industries, including automotive, kitchen appliance manufacturing, and high-temperature environments. These qualities, along with the availability of different ferritic stainless steel grades, make this material a versatile and reliable choice for a variety of applications.

Overview of common grades

Ferritic stainless steel is a type of ferritic steel that contains a significant amount of chromium, which gives it excellent corrosion resistance and high temperature strength. Some of the common uses of ferritic stainless steel include automotive components, kitchen appliances, architectural structures and industrial equipment.

There are various grades of ferritic stainless steel available in the market, each with its own composition and properties. One such grade is Nitronic 50HS, which is a high-strength ferritic stainless steel that exhibits excellent corrosion resistance and mechanical properties. It is often used in applications requiring high strength and toughness, such as pump shafts, marine hardware and valves.

Another common grade of ferritic stainless steel is SUS430, which has a composition containing 16-18% chromium and a small amount of nickel. It is widely used in kitchen appliances, cookware, and automotive trim due to its resistance to corrosion and oxidation. SUS430 is also known for its good formability and weldability, making it a preferred choice in various industries.

| Grade | Composition | Typical Applications |

|---|---|---|

| Nitronic 50HS | Chromium, nickel, molybdenum, nitrogen | Pump shafts, marine hardware, valves |

| SUS430 | Chromium, nickel | Kitchen appliances, cookware, automotive trim |

Ferritic stainless steel grades are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and good formability. These grades offer a cost-effective alternative to other stainless steel types, such as austenitic stainless steel. They are suitable for applications where toughness, durability, and resistance to corrosion and oxidation are important factors to consider.

Key properties of each grade

There are several different grades of ferritic stainless steel, each with its own unique set of properties and uses.

- Nitronic 50HS: Nitronic 50HS is a high-strength, low-temperature ferritic stainless steel. It contains a high level of nitrogen, which enhances its strength and corrosion resistance. This grade is often used in applications where high strength and excellent corrosion resistance are required, such as in marine environments or chemical processing plants.

- SUS430: SUS430 is a low-cost ferritic stainless steel grade that offers good corrosion resistance and formability. It is commonly used in a wide range of applications, including kitchen appliances, automotive trim, and architectural components. SUS430 is also known for its magnetic properties, making it suitable for applications where magnetic permeability is desired.

Other ferritic stainless steel grades, such as ferritic stainless steel 409 and ferritic stainless steel 446, are commonly used in exhaust systems for automotive and industrial applications. These grades offer good oxidation resistance and thermal conductivity, making them suitable for high-temperature environments. Additionally, ferritic stainless steel is often used in the production of cooking utensils, heat exchangers and construction materials due to its cost-effective nature and good weldability.

Overall, the key properties of each grade of ferritic stainless steel make them suitable for a wide range of applications. Whether it’s for high-strength and corrosion-resistant applications or low-cost and formable components, ferritic stainless steel offers a versatile solution for various industries.

Nitronic 50HS: A Specialized Ferritic Alloy

One of specialized ferritic stainless steel composition is Nitronic 50HS. Nitronic 50HS is a high-strength, nitrogen-strengthened ferritic stainless steel that offers exceptional mechanical properties and excellent resistance to corrosion.

Nitronic 50HS belongs to the group of ferritic stainless steel grades, which have a ferritic metal structure consisting mainly of iron and chromium. In addition to chromium, Nitronic 50HS also contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to corrosion and increase its strength.

Some of the uses of Nitronic 50HS in various industries include marine equipment, chemical processing plants, oil and gas industry and aerospace applications. Its high strength and corrosion resistance properties make it ideal for components subjected to high stress and aggressive environments. Moreover, Nitronic 50HS offers good ductility and weldability, allowing for easy fabrication and installation in different applications.

SUS430 Material: Properties and Applications

SUS430 is a type of ferritic stainless steel belonging to the SUS400 series. It is widely used due to its excellent resistance to corrosion, high thermal conductivity, and good formability. The ferritic stainless steel composition of SUS430 is characterized by a high chromium content (around 16%), which provides its corrosion resistance. Additionally, it contains small amounts of carbon and other elements to improve its mechanical properties. SUS430 material is known for its low ductility, but it can be hardened by heat treatment to increase its strength.

The versatility of SUS430 material makes it suitable for various ferritic stainless steel applications. Due to its corrosion resistance, it is commonly used in environments with exposure to humidity, such as kitchen equipment, automotive trim, and washing machine drums. Its high thermal conductivity makes it a preferred choice for heat exchangers and heating elements. SUS430 is also utilized in the manufacturing of nitronic 50hs due to its good weldability and low cost compared to other ferritic stainless steel grades.

| Properties | Value |

|---|---|

| Ferritic Stainless Steel Composition | 16% chromium, small amounts of carbon and other elements |

| Ferritic Stainless Steel Price | Lower compared to other stainless steel grades |

| Ferritic Stainless Steel Uses | Kitchen equipment, automotive trim, washing machine drums, heat exchangers, heating elements, nitronic 50hs |

| Ferritic Stainless Steel Properties | Corrosion resistance, high thermal conductivity, good formability, low ductility |

Key Insight: SUS430 material is a ferritic stainless steel that offers excellent corrosion resistance, making it suitable for various applications in humid environments. Its high thermal conductivity and good formability further contribute to its versatility.

In-depth look at SUS430 material

The composition of SUS430 material typically consists of 16-18% chromium, 0.75% max nickel, 0.12% max carbon, and small amounts of other elements such as manganese and silicon. This composition gives the material its unique properties, including good formability, high heat resistance, and magnetic properties.

One of the advantages of using SUS430 material is its relatively low cost compared to other stainless steel grades. The ferritic stainless steel price is often more affordable, making it a popular choice for applications where cost is a significant factor.

| Grade | Composition | Applications | Properties |

|---|---|---|---|

| SUS430 | 16-18% chromium, 0.75% max nickel, 0.12% max carbon | Automotive, household appliances, kitchen utensils | Good formability, high heat resistance, magnetic properties |

| Nitronic 50HS | Cr 20.5-23.5%, Ni 11.5-13.5%, Mn 4-6%, Mo 1.5-3%, N 0.20-0.40% | Pump shafts, marine hardware, valve stems | Excellent corrosion resistance, high strength, good weldability |

SUS430 material is a versatile ferritic stainless steel that offers good corrosion resistance, formability, and affordability. Its magnetic properties and heat resistance make it suitable for a wide range of applications in various industries. Whether it’s in the automotive sector, household appliances, or the kitchen, SUS430 can meet the demanding requirements of different applications.

Specific uses and advantages

One specific use of ferritic stainless steel is in automotive exhaust systems. The high temperature and corrosive environment of exhaust gases require a material that can withstand these conditions, and ferritic stainless steel is an excellent choice. Its high chromium content provides good resistance to oxidation and corrosion, while its low carbon content improves weldability and formability.

- Ferritic stainless steel price: The lower cost of ferritic stainless steel compared to other grades makes it an economical choice for various applications.

- Ferritic stainless steel properties: Ferritic stainless steel has good resistance to corrosion, high-temperature oxidation, and stress corrosion cracking. It also has excellent weldability and formability.

- Uses of ferritic stainless steel: Ferritic stainless steel is used in automotive exhaust systems, heat exchangers, appliances, kitchen equipment, and decorative applications.

- Ferritic stainless steel composition: Ferritic stainless steel is primarily composed of chromium and iron, with small amounts of carbon, manganese, and other elements.

- Ferritic stainless steel applications: Ferritic stainless steel is used in various industries, including automotive, aerospace, construction, and food processing.

- Ferritic stainless steel uses: Ferritic stainless steel is used for exhaust systems, heat exchangers, cooking utensils, sinks, and decorative applications.

In summary, ferritic stainless steel offers a cost-effective solution for applications where high corrosion resistance is not required. Its unique properties, such as good weldability, formability, and resistance to high-temperature oxidation, make it a versatile material for various industries and applications.

Price Dynamics in Ferritic Stainless Steel

The composition of ferritic stainless steel plays a significant role in determining its price. Different grades of ferritic stainless steel may contain varying amounts of alloying elements such as chromium, nickel and molybdenum. These elements not only enhance the corrosion resistance and mechanical properties of the steel but also affect its cost. For example, ferritic stainless steel with a higher chromium content tends to be more expensive due to the increased corrosion resistance it provides.

Additionally, the properties and uses of ferritic stainless steel impact its price. Ferritic stainless steel magnetic properties also make it useful in certain applications, such as magnetic resonance imaging (MRI) equipment. The specific requirements and demand for these properties and uses can influence the price of ferritic stainless steel.

Factors influencing pricing

The pricing of ferritic stainless steel is influenced by several factors. One of the main factors is the composition of the steel. Ferritic stainless steel is primarily composed of iron and chromium, with other alloying elements such as molybdenum, nickel, and titanium added in varying amounts. The composition of the steel affects its performance and determines its cost.

- The grade of ferritic stainless steel is also a significant factor in pricing. Different grades have different compositions and properties, and some may be more expensive to produce than others. For example, Nitronic 50HS is a popular ferritic stainless steel grade that contains high levels of nitrogen and is known for its excellent corrosion resistance. Due to its superior properties, it may have a higher price compared to other ferritic stainless steels.

- Market demand and supply also play a role in determining the price of ferritic stainless steel. If there is high demand for ferritic stainless steel, the price may be higher due to limited supply. Conversely, if the market is saturated with ferritic stainless steel, the price may be lower.

- The cost of raw materials, such as iron, chromium, and other alloying elements, can also impact the pricing. If the cost of these raw materials increases, the price of ferritic stainless steel may rise as well.

In conclusion, the pricing of ferritic stainless steel is influenced by factors such as the composition, grade, market demand and supply, and the cost of raw materials. It is essential for manufacturers and consumers to consider these factors when pricing and purchasing ferritic stainless steel for various applications.

Comparison with other stainless steel types

One popular alternative to ferritic steel is Nitronic 50HS, which is a high-strength austenitic stainless steel alloy. While Nitronic 50HS may have superior strength and corrosion resistance, it is significantly more expensive than ferritic stainless steel. The SUS430 material, which is a ferritic stainless steel grade, is a more cost-effective option for applications where high strength is not a crucial requirement.

When comparing the composition of ferritic stainless steels with other types, it is important to note that ferritic stainless steels have a higher chromium content but lower nickel content. This composition makes ferritic stainless steels less susceptible to corrosion caused by chloride ions, making them ideal for applications in environments with high chloride concentrations, such as coastal areas or swimming pools.

Table: Comparison of Ferritic Stainless Steel and Other Stainless Steel Types

| Property | Ferritic Stainless Steel | Nitronic 50HS | SUS430 Material |

|---|---|---|---|

| Strength | Lower strength compared to Nitronic 50HS | Higher strength | Lower strength |

| Corrosion Resistance | Good resistance to chloride corrosion | Superior corrosion resistance | Good resistance to chloride corrosion |

| Cost | Lower cost compared to Nitronic 50HS | Higher cost | Lower cost |

| Applications | Automotive exhaust systems, kitchen appliances, architectural structures | Chemical processing, marine environments, aerospace | Kitchen appliances, industrial equipment, automotive trim |

While it may have lower strength compared to alloys like Nitronic 50HS, ferritic stainless steel is versatile and widely used in various applications. Its unique properties make it suitable for automotive, industrial, and architectural applications, providing a reliable and efficient material choice.

Composition Insights: Ferritic Stainless Steel

Ferritic stainless steel is a type of ferritic metal that contains high amounts of chromium, typically ranging from 10.5% to 30%. The presence of chromium in the composition of ferritic steel provides excellent corrosion resistance and makes it highly resistant to tarnish and staining. Additionally, ferritic stainless steel exhibits good high-temperature oxidation resistance compared to other stainless steel grades.

| Applications of Ferritic Stainless Steel: |

|---|

| Ferritic stainless steel is commonly used in the production of automotive exhaust systems due to its high temperature and oxidation resistance. |

| It is also widely used in kitchen appliances, such as sinks, countertops, and cooking utensils, as it provides excellent resistance to corrosion and staining caused by food and liquids. |

| Furthermore, ferritic stainless steel is utilized in the construction industry for applications that require high strength and resistance to atmospheric corrosion, such as bridges, building facades, and structural components. |

| Ferritic stainless steel is also commonly found in the medical and pharmaceutical industries due to its corrosion resistance and ease of fabrication. |

Overall, ferritic stainless steel offers a combination of good corrosion resistance, high temperature resistance, and strength, making it a versatile material for a wide range of applications. Its composition and properties make it suitable for various industries, including automotive, construction, kitchenware, and medical. With its excellent performance and reasonable ferritic stainless steel price, it is a popular choice for numerous applications.

Breakdown of common compositions

One common composition of ferritic stainless steel is Nitronic 50HS, which is a high-strength, low-alloy grade that offers good corrosion resistance and high mechanical properties. Other common compositions of ferritic stainless steel include SUS430, which is a general-purpose grade with good formability and corrosion resistance.

Ferritic stainless steel properties are determined by their composition, which typically includes a high level of chromium and low levels of carbon and nickel. The high chromium content provides excellent corrosion resistance, while the low carbon and nickel levels contribute to the material’s good formability and weldability. Ferritic stainless steel grades can vary in their composition to optimize specific properties for different applications.

Ferritic Stainless Steel Grades:

- SUS410: Offers good corrosion resistance and moderate strength.

- SUS430: Provides good formability and corrosion resistance.

- SUS446: Offers excellent oxidation resistance at high temperatures.

Ferritic Stainless Steel Applications:

- Automotive exhaust systems: Ferritic stainless steel is commonly used in exhaust systems due to its high-temperature oxidation resistance and good corrosion resistance.

- Appliances: Ferritic stainless steel is used in appliances such as kitchen sinks, cooking utensils, and refrigerator interiors due to its good formability and corrosion resistance.

- Architectural applications: Ferritic stainless steel is used in architectural applications such as handrails, elevator panels, and decorative trim due to its aesthetic appeal and corrosion resistance.

The different grades of ferritic stainless steel have different compositions to optimize specific properties such as corrosion resistance, formability, and strength. Whether it is for automotive, appliance, or architectural applications, ferritic stainless steel provides reliability and durability.

Influence on Performance

One of the key factors that influence the performance of ferritic stainless steel is its composition. For example, SUS430 is a commonly used ferritic stainless steel material that contains chromium as the main alloying element. The addition of chromium provides excellent corrosion resistance, making it suitable for applications where exposure to moisture or harsh environments is expected. The composition of ferritic stainless steel can also include other elements such as molybdenum, nickel, and nitrogen, which further enhance its mechanical properties and resistance to corrosion.

- Ferritic stainless steel is a type of ferritic metal that exhibits a body-centered cubic (BCC) crystal structure. This crystal structure contributes to its high ductility and excellent formability, making it easily weldable and suitable for fabrication processes. It also offers good thermal conductivity, which is beneficial in applications where heat transfer is important.

- The price of ferritic stainless steel is another factor that influences its performance. Compared to austenitic stainless steels, ferritic stainless steel is generally more cost-effective, making it a preferred choice for applications where cost is a significant consideration. This affordability does not compromise the material’s performance, as it still offers excellent corrosion resistance and mechanical properties.

- Ferritic stainless steel grades have different compositions and properties, which affect their performance in specific applications. For example, ferritic stainless steel grade 430 has a higher chromium content than grade 409, providing enhanced resistance to corrosion and oxidation. The selection of the appropriate ferritic stainless steel grade is crucial to ensure optimal performance and longevity in various applications.

| Ferritic Stainless Steel Applications | Ferritic Stainless Steel Grades | Ferritic Stainless Steel Properties |

|---|---|---|

| Automotive exhaust systems | Grade 409, Grade 439 | High resistance to corrosion and oxidation, good heat resistance |

| Appliances (e.g., refrigerators, washing machines) | Grade 430, Grade 434, Grade 436 | Excellent formability, good resistance to corrosion |

| Construction (e.g., architectural applications) | Grade 444, Grade 446 | High strength, good weldability, resistance to corrosion in chloride environments |

| Petrochemical and chemical processing | Grade 430, Grade 446 | Excellent resistance to corrosion and oxidation, high temperature stability |

By understanding the specific requirements of a given application and selecting the appropriate ferritic stainless steel grade, one can ensure optimal performance, cost-effectiveness, and longevity of the material.

Utilization Across Industries

Ferritic stainless steel grades, such as SUS430 material and Nitronic 50HS, have a wide range of applications across various industries. They are known for their excellent resistance to corrosion, high temperature resistance, and good formability, making them suitable for a variety of uses.

One of the key uses of ferritic stainless steel is in the automotive industry. It is used for components such as exhaust systems, catalytic converters, and heat exchangers. The ferritic stainless steel composition provides excellent corrosion resistance, even in high-temperature environments, which is essential for these applications. Additionally, the high formability of ferritic stainless steels allows for complex designs and easy fabrication of automotive parts.

- Ferritic stainless steel properties also make them ideal for kitchen appliances and equipment. They are commonly used in the manufacturing of ovens, refrigerators, microwaves, and dishwashers. The resistance to corrosion and heat, combined with their aesthetic appeal, makes ferritic stainless steel a popular choice in the kitchen.

- In the chemical and petrochemical industries, ferritic stainless steel is utilized for its resistance to a wide range of corrosive chemicals and high temperatures. It is commonly used in equipment such as storage tanks, piping, and reactors. The durability and corrosion resistance of ferritic stainless steel make it a reliable choice for the harsh operating conditions in these industries.

Note: Ferritic stainless steel price can vary depending on the specific grade and market conditions. However, its versatility and performance in various applications make it a cost-effective choice in many industries.

In summary, ferritic stainless steel offers a wide range of applications across industries due to its excellent resistance to corrosion, high temperature resistance, and good formability. Its uses include automotive parts, kitchen appliances, and equipment in the chemical and petrochemical industries. The diverse properties and cost-effectiveness of ferritic stainless steel make it a valuable material in a variety of industrial applications.

Energy sector applications

Ferritic stainless steel has several applications in the energy sector, thanks to its unique combination of properties and affordable price compared to other stainless steel grades. It finds use in various energy production, transmission, and storage facilities due to its corrosion resistance, high temperature strength, and magnetic properties.

One of the main uses of ferritic stainless steel in the energy sector is in power plants. Power plants, whether they are nuclear, gas, or coal-fired plants, require materials that can withstand high temperatures and corrosive environments. Ferritic stainless steel grades, such as SUS430 and Nitronic 50HS, offer excellent resistance to oxidation, scaling, and pitting in such harsh conditions. They can be used in the construction of condenser tubing, heat exchangers, and boilers.

- Power plant boilers: Ferritic stainless steels are commonly used in the construction of power plant boilers due to their high resistance to corrosion and their ability to handle high temperatures. The composition of ferritic stainless steel grades gives them the strength to withstand the pressures and temperatures found in boilers without degrading or corroding. This makes them a reliable choice for energy generation.

- Wind turbines: Ferritic stainless steel is also used in the construction of wind turbines, where its high corrosion resistance is crucial. It is used in components such as tower structures and rotor hubs, which are exposed to outdoor conditions and can be subject to harsh weather and corrosive environments. The use of ferritic stainless steel ensures the longevity and durability of these components.

Did you know? Ferritic stainless steel is a type of stainless steel that is primarily made up of iron and chromium, with small amounts of carbon and other elements. It is magnetic and has a lower carbon content than austenitic stainless steel, which gives it better resistance to corrosion and thermal stability.

In summary, ferritic stainless steel finds extensive use in the energy sector due to its corrosion resistance, strength at high temperatures, and magnetic properties. Its affordability compared to other stainless steel grades makes it an attractive choice for various applications in power plants, wind turbines, and other energy-related facilities.

Marine and Offshore Uses of Ferritic Stainless Steel

Ferritic stainless steel is widely used in marine and offshore applications due to its excellent corrosion resistance and cost-effectiveness. It offers a viable alternative to other corrosion-resistant materials, such as austenitic stainless steel and nickel alloys, in environments where exposure to seawater, salt, and harsh weather conditions is common.

One of the main advantages of ferritic stainless steel in marine and offshore settings is its ability to resist pitting and crevice corrosion. This makes it highly suitable for various components and structures, including ship hulls, propellers, offshore platforms, and marine equipment. Additionally, ferritic stainless steel offers good strength and toughness, allowing it to withstand the extreme conditions and stresses that can occur in marine environments.

Some specific examples of ferritic stainless steel grades commonly used in marine and offshore applications include SUS430, which is known for its high resistance to corrosion and oxidation; NITRONIC 50HS, a high-strength variant that offers superior toughness and wear resistance; and other ferritic stainless steels with different compositions and properties tailored to specific requirements.

| Ferritic Stainless Steel Grade | Composition | Properties | Applications |

|---|---|---|---|

| SUS430 | 17% chromium, 0.12% carbon | High resistance to corrosion and oxidation | Ship hulls, marine equipment, propellers |

| NITRONIC 50HS | Cr-Ni-Mo-N | High strength, toughness, and wear resistance | Offshore platforms, marine structures |

Ferritic stainless steel is a versatile material that finds extensive use in marine and offshore industries due to its corrosion resistance, strength, and cost-effectiveness. It not only provides long-term durability in harsh marine environments but also offers excellent performance in terms of maintenance and repair. With its various grades and compositions, ferritic stainless steel caters to different marine and offshore applications, ensuring the safety and efficiency of structures and equipment.

Chemical processing

Ferritic stainless steel is widely used in the chemical processing industry due to its unique composition and properties. This type of stainless steel, such as Nitronic 50HS and SUS430 material, is primarily composed of iron and chromium, with smaller amounts of carbon, manganese, and other elements. The ferritic structure of this stainless steel makes it highly resistant to corrosion and oxidation, making it an ideal choice for applications in the chemical processing industry.

Ferritic stainless steel offers a range of benefits for chemical processing applications. Firstly, its resistance to corrosion ensures that it can withstand the harsh chemical environments that are often present in this industry. This makes it suitable for use in equipment such as reactors, heat exchangers, and piping systems. Additionally, the ferritic stainless steel grades exhibit excellent mechanical properties, including high strength and toughness, which make them capable of withstanding the extreme pressures and temperatures often encountered in chemical processes.

- Ferritic stainless steel is also favored in the chemical processing industry for its cost-effectiveness. Compared to other stainless steel types, ferritic stainless steel is generally more affordable, making it a popular choice for budget-conscious projects.

- Furthermore, ferritic stainless steel’s magnetic properties make it easier to work with in certain chemical processing applications. For example, it can be beneficial to use ferritic stainless steel for magnetic separation or when working with electromagnetic devices.

In summary, due to its unique composition, ferritic stainless steel offers numerous advantages for chemical processing applications. Its resistance to corrosion, excellent mechanical properties, cost-effectiveness, and magnetic properties make it a versatile choice for various equipment and systems in the chemical processing industry.

Future Trends and Innovations

The future of ferritic stainless steel applications looks promising, as ongoing research and development efforts continue to explore new uses and properties for this versatile material. One of the key areas of focus is the enhancement of ferritic stainless steel compositions to improve specific properties, such as corrosion resistance and strength. This involves adjusting the alloying elements and optimizing the manufacturing processes to create ferritic stainless steels with enhanced performance.

New grades of ferritic stainless steels are being developed to meet the increasing demands of various industries. For example, there is a growing need for ferritic stainless steels with high temperature oxidation resistance, which can be used in applications such as exhaust systems in automotive and power generation sectors. These new grades of ferritic stainless steels offer improved thermal stability, corrosion resistance and mechanical properties, making them ideal for such demanding environments.

In addition to compositional changes, innovations in manufacturing processes are also being explored to further improve the properties of ferritic stainless steels. One such example is the use of advanced heat treatment techniques to enhance the mechanical properties of ferritic stainless steels, such as increasing their strength and ductility. These advancements in manufacturing processes contribute to the overall improvement of ferritic stainless steel properties and expand their range of applications.

Emerging technologies in ferritic stainless steel

Ferritic stainless steel is a versatile material that is widely used in various industries due to its excellent mechanical properties and corrosion resistance. As technology continues to advance, there are several emerging technologies that are being developed to enhance the properties and uses of ferritic stainless steel grades.

1. Development of new ferritic stainless steel compositions

Research and development efforts are focused on creating new ferritic stainless steel compositions with improved properties. By adjusting the chemical composition, researchers can optimize the balance between strength, corrosion resistance, and other desired characteristics. For example, the addition of elements like molybdenum and nitrogen can enhance the strength and pitting resistance of ferritic stainless steels. These new compositions have the potential to expand the range of applications for ferritic stainless steel by meeting the requirements of demanding industries.

2. Advanced processing techniques for ferritic stainless steel

Advancements in processing techniques are also being explored to further enhance the properties of ferritic stainless steel. One such technique is thermo-mechanical processing, which involves subjecting the material to a combination of high temperature and controlled deformation. This process can refine the microstructure of the ferritic stainless steel, leading to improved mechanical properties such as higher strength and toughness. Additionally, advanced heat treatment methods, such as quenching and tempering, can be employed to optimize the properties of ferritic stainless steel for specific applications.

In conclusion, the development of new ferritic stainless steel compositions and advancements in processing techniques are driving the emergence of new technologies in the field. These technologies have the potential to expand the range of uses for ferritic stainless steel by improving its mechanical properties and corrosion resistance. As a result, ferritic stainless steel is becoming an increasingly popular choice in industries such as automotive, construction, and energy.

Anticipated Advancements

With ongoing advancements in technology and materials science, the future looks promising for the further development and use of ferritic stainless steel in various applications. One of the anticipated advancements is the improvement in the composition and properties of ferritic stainless steel grades, making them even more versatile and suitable for a wider range of applications.

Researchers are constantly exploring new ways to enhance the mechanical and corrosion resistance properties of ferritic stainless steels. This includes developing innovative alloying elements and heat treatment processes that can improve their strength, ductility, and resistance to oxidation and corrosion. By tailoring the composition and microstructure of the ferritic steel, it is possible to achieve specific properties that meet the requirements of different industries, such as automotive, aerospace, and energy.

In addition to material improvements, advancements in processing technologies are also expected. These advancements can lead to cost-effective manufacturing methods for producing complex shapes and components using ferritic stainless steels. This will further expand their uses and applications, as well as potentially reduce the overall production costs for industries that heavily rely on ferritic stainless steel, such as the automotive industry.

Conclusion

In conclusion, ferritic stainless steel is a versatile material that finds numerous applications in various industries. Its composition, which typically includes high levels of chromium and low levels of carbon, provides excellent corrosion resistance, making it suitable for use in environments where other steels would fail.

Ferritic stainless steel grades such as SUS430 have a wide range of uses, including in appliances, automotive parts, and kitchenware. The material’s high strength and durability make it ideal for these applications, as it can withstand the demands of everyday use without succumbing to wear and tear.

Additionally, the ferritic structure of these steels allows for easy fabrication and welding, further increasing their versatility and applicability. The properties of ferritic stainless steel, including good formability, magnetic behavior and resistance to stress corrosion cracking, make it a preferred choice for many engineering and construction projects.

Overall, ferritic stainless steel offers a cost-effective solution for various industries, thanks to its wide range of applications, favorable properties, and competitive price. Whether it is used in the construction of bridges or in the manufacturing of household appliances, ferritic stainless steel has proven to be a reliable and efficient material that meets the needs of diverse engineering projects.

Summarize key points

Ferritic stainless steel is a type of stainless steel that is known for its high resistance to corrosion, excellent mechanical properties, and low cost. It is composed of mainly ferritic material, which is a crystalline structure that provides strength and durability. Ferritic stainless steel is available in various grades, with different compositions and properties. Some common grades include Nitronic 50HS and SUS430.

- Ferritic stainless steel has a lower chromium content compared to other stainless steel types, but it still offers good corrosion resistance, especially in high-temperature environments.

- One of the advantages of ferritic stainless steel is its lower price compared to other stainless steel grades.

- Ferritic stainless steel finds applications in various industries such as automotive, architectural, and chemical processing.

- Due to its excellent mechanical properties, ferritic stainless steel is commonly used in structural components, heat exchangers, and exhaust systems.

- The uses of ferritic stainless steel also extend to household appliances, kitchenware, and food processing equipment.

In summary, ferritic stainless steel is a versatile material with a range of applications due to its properties, grades, and affordable price. Its corrosion resistance, strength, and durability make it a suitable choice for various industries and everyday products.

The Significance of Ferritic Stainless Steel in Modern Industries

Ferritic stainless steel is a versatile material that is widely used in modern industries due to its unique properties and composition. It is composed primarily of iron and chromium, with small amounts of other elements such as carbon, silicon, and manganese. This composition gives ferritic stainless steel excellent resistance to corrosion and high-temperature oxidation, making it suitable for a wide range of applications.

One of the key advantages of ferritic stainless steel is its affordability compared to other stainless steel grades. This makes it a cost-effective choice for industries that require corrosion-resistant materials. Additionally, ferritic stainless steel has good formability and weldability, allowing for easy fabrication and shaping into various products.

Ferritic stainless steel finds extensive use in industries such as automotive, construction and kitchenware. In the automotive industry, it is utilized for exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion. In the construction industry, ferritic stainless steel is used for structural elements, decorative facades, and outdoor installations, where durability and aesthetic appeal are crucial. In the kitchenware sector, ferritic stainless steel is popular for its resistance to staining and corrosion, making it ideal for cutlery, cookware, and appliances.

In conclusion, ferritic stainless steel plays a vital role in modern industries due to its unique properties, affordability, and versatility. Its corrosion resistance, high-temperature oxidation resistance, and ease of fabrication make it suitable for a wide range of applications. From automotive to construction to kitchenware, ferritic stainless steel is utilized in numerous sectors, contributing to the advancement and efficiency of modern industries.